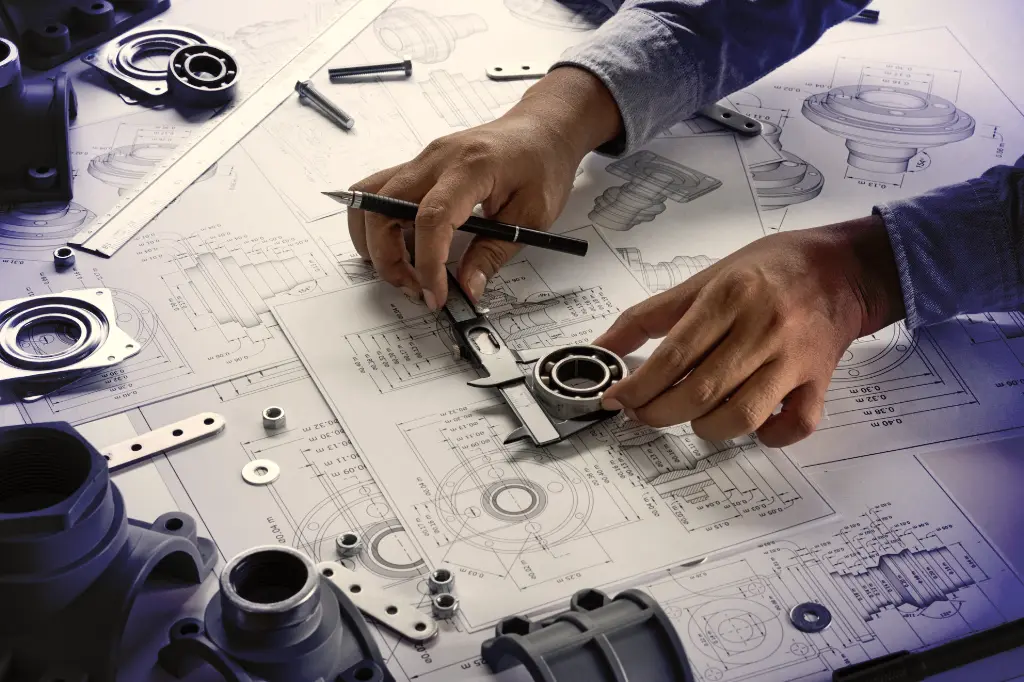

Precision at Every Step

Even the smallest deviation can impact performance. That’s why we apply a meticulous approach to quality at every stage of the CNC machining process—ensuring every part meets your exact specifications from design to delivery.

- Design for Manufacturability (DFM) Review – Quality starts before production. Our automated online DFM review checks your CAD design for manufacturability, flagging potential issues like thin walls, deep holes, or tight radii. This early feedback helps prevent costly delays or rework. Every order is also manually reviewed by our CNC experts for additional assurance.

- Advanced CNC Programming – Our skilled programmers use state-of-the-art CAM software to generate precise, efficient toolpaths. Each program is reviewed for accuracy and optimized for repeatable results, whether you need one prototype or a full production run.

- Production Monitoring – During machining, we employ real-time machine monitoring to maintain exact tolerances. Our machinists oversee each operation—whether on a 3-axis, 5-axis, or mill-turn CNC machine—to ensure consistent performance.

- In-Process Inspections – We perform dimensional checks throughout production using automated probing and precision metrology tools. This allows us to correct any deviations before they impact the final part.

- Final Quality Assurance – Before shipping, every part undergoes a full inspection. We verify all critical dimensions, check surface finishes, and ensure the part meets your specifications—both functionally and cosmetically.

Part Finishing with Precision

Our quality approach also extends to the finishing stage. Whether your part requires bead blasting, deburring, laser engraving, or advanced finishes like anodizing or powder coating, we ensure that every finish is applied with precision. We understand that these details not only enhance the appearance of your part but can also affect its performance and longevity.

Continuous Improvement and Innovation

At Rapid CNC Parts, quality is a continuous pursuit. We’re always looking for ways to improve our processes, adopt new technologies, and refine our approach to manufacturing.

Ongoing Training – Our team regularly undergoes training to stay up-to-date with the latest in CNC machining, 3D printing technologies, and quality control practices.

Technology Upgrades – We continuously invest in cutting-edge technology to improve both the efficiency and quality of our production. From the latest CNC machines to advanced 3D printing systems, we leverage the best tools available to deliver high-quality parts.

Aligned to Industry Standards

Our processes are built to align with ISO 9001:2015 and AS9100 quality management principles, globally recognized frameworks that emphasize consistency, efficiency, traceability, and customer satisfaction—values we integrate into every CNC-machined part we produce. While we are not currently certified, we are actively building and refining our quality management systems with the goal of achieving certification as our business grows.