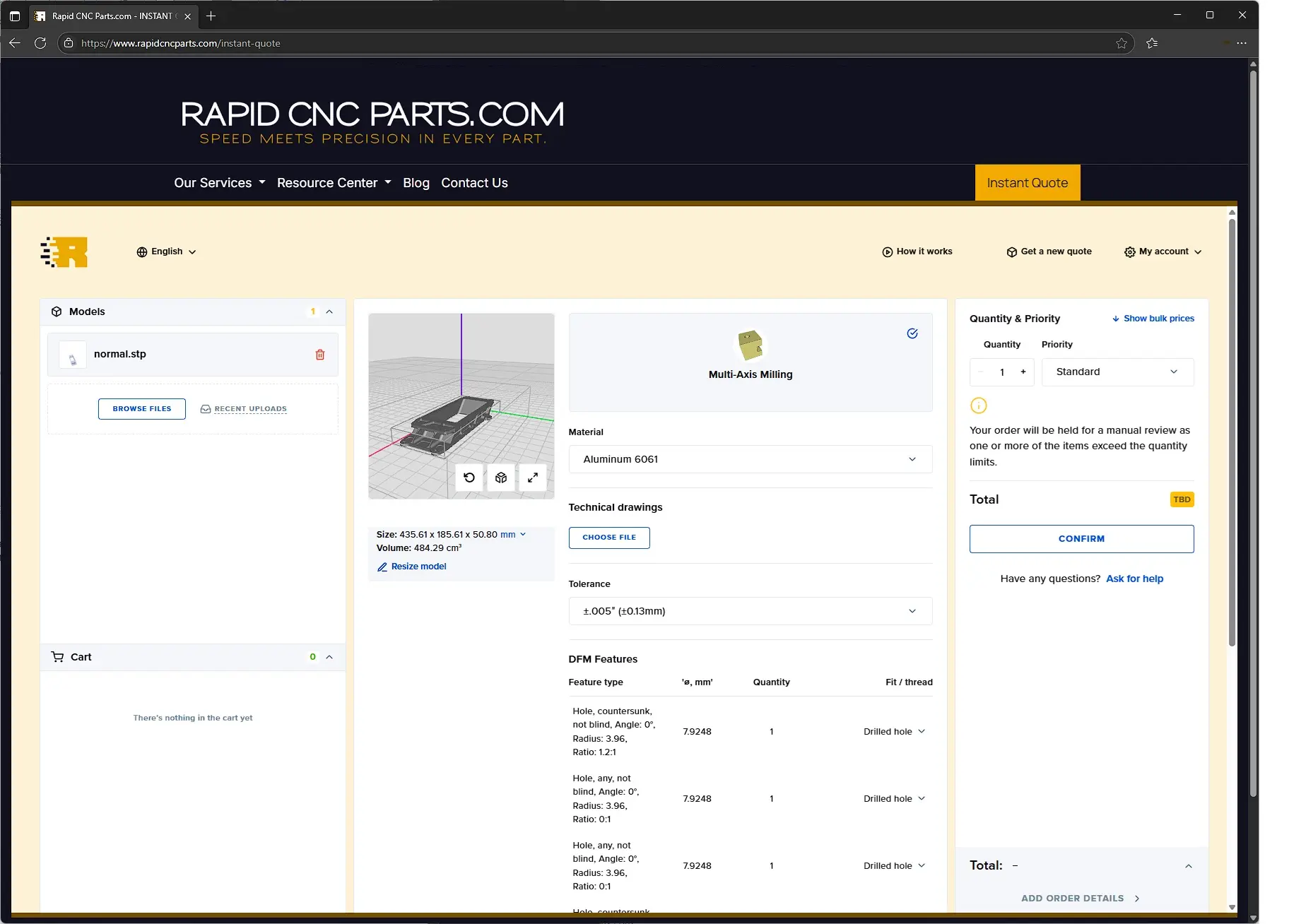

Step 1: Instant Quote

The journey starts with our Instant Quote tool. We’ve made the quoting process as simple and efficient as possible to save you time and ensure you have the information you need quickly.

How It Works:

- Upload Your Part – Start by uploading your part’s design file directly into our system. Our tool accepts a variety of file formats, ensuring compatibility with your CAD model.

- Choose Your Process – Select the type of manufacturing process that suits your needs: either 3D Printing or CNC Machining.

- Select Material & Finish – Choose from a variety of high-quality materials, such as plastics, metals, and composites, and specify the surface finish you require for your part.

- Specify Quantities – Let us know how many parts you need, whether it’s a small batch or a larger production run.

Once your details are entered, our instant quote engine calculates an accurate price in real-time, giving you a quick and reliable quote for your order.

Pro Tip: Use our Design Guidelines to ensure machinability, the best price, and fastest turnaround!

Step 2: DFM Review

Once your quote is generated, our system automatically performs a Design for Manufacturability (DFM) review to assess the overall manufacturability of your part. Using the geometry from your uploaded design, our engine runs automated checks to ensure that your part can be effectively produced using your chosen manufacturing process.

What Happens Next?:

- Passes the DFM Check: If your part passes the manufacturability review, the instant quote is finalized, and you can proceed with placing your order.

- Does Not Pass the DFM Check: If the part doesn’t pass the automated checks, it’s typically due to features like taps/threads or geometries, pockets or walls that require additional review. In these cases, our system flags the part for expert attention.

See our Design Guidelines and Design for Manufacturing pages for a comprehensive list of things to check for in your design to avoid the need for manual review.

When the system detects potential design issues, we may request a PDF drawing of your part to clarify details or to detail features such as:

- Thread specifications

- Tolerances on specific geometry

- Surface finishes outside of standard options

This ensures that we understand any special requirements before moving forward with manufacturing which ensures your part is produced in accordance to specifications.

Step 3: Review & Confirmation (Manual Review)

If your part requires additional review, one of our machining experts may reach out to you directly or you will receive a quote if enough information was included to complete a manual quote. In this part of the process, our team will assess the part, address any additional design complexities, and provide you with an updated quote that reflects any adjustments needed for manufacturing.

Once reviewed and confirmed, we make this part easy by sending the quote back to you with a shopping cart so you can complete your order.

Step 4: Final Review & Payment

Before finalizing your order, you’ll have the opportunity to review your parts in detail through our 3D Viewer. This interactive view allows you to see a detailed, 3D representation of your part, ensuring everything is as expected before you place the order.

In this step, we provide:

- Estimated Lead Time – Get an estimated lead time for your order so you can plan accordingly and track the progress of your part.

- Shipping Options – Choose from a variety of shipping methods that best suit your needs, whether you require expedited shipping or standard delivery.

- Payment Options – Once you're confident in your order, you can proceed to payment. We accept most major credit cards, making the payment process quick, easy, and secure.

After confirming the details and completing your payment, your order will be processed and sent to production.

Step 5: Final Order Review by Our Staff

Once we receive your confirmed order, our process continues with a thorough review by our expert team before it is sent to production during programming. We ensure that every part meets our high standards for manufacturability and keep you informed each step of the way.

Order Review Includes:

Automated DFM Check – For most orders, the Design for Manufacturability (DFM) review is conducted automatically by our system.

Manual DFM Review – If our system flags any complexities—such as threads, intricate geometry, or special tolerances—requiring further review, our team steps in. We carefully assess the design, checking for any potential issues that may affect manufacturability or production quality.

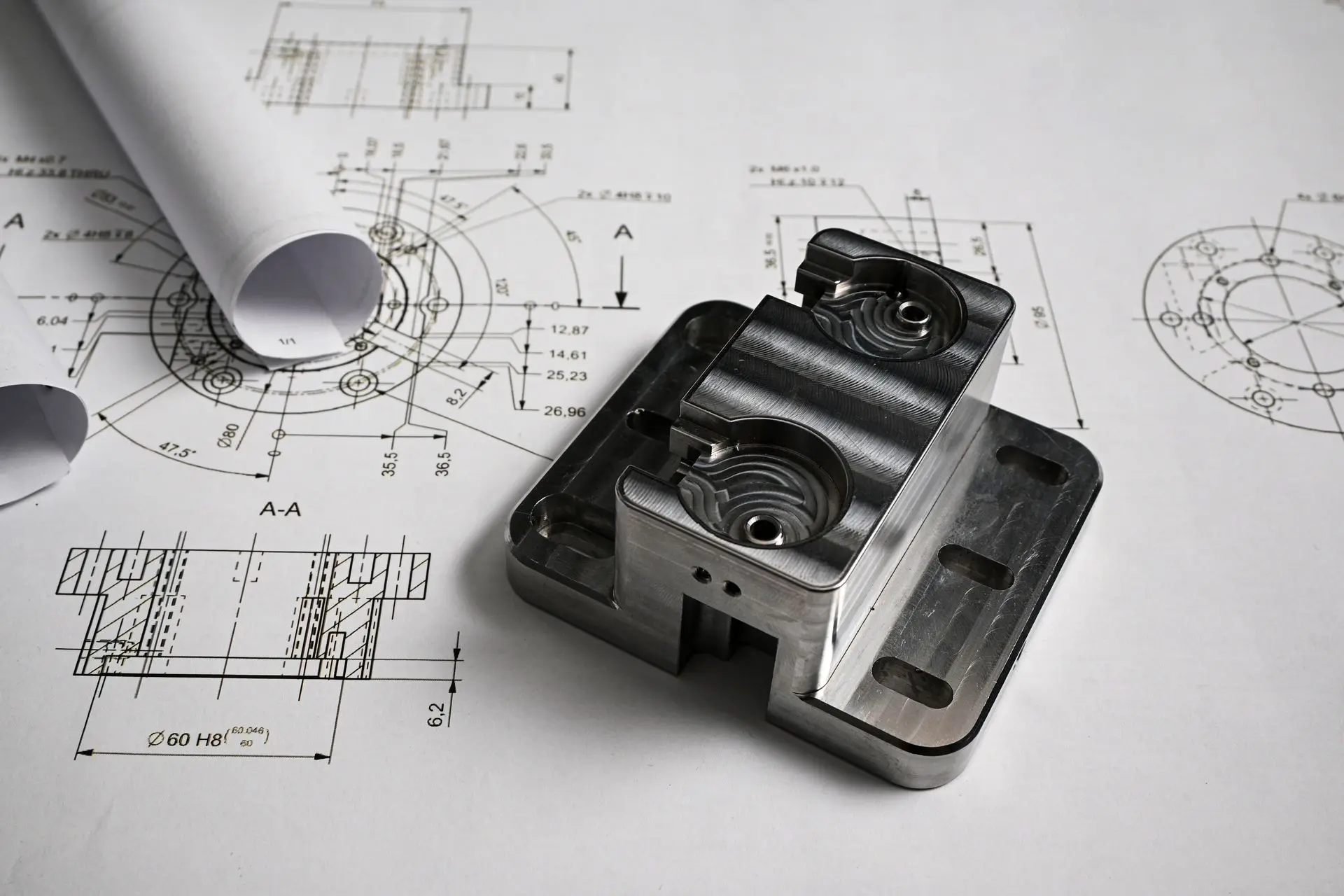

Step 6: Programming and Production

Once your order has been reviewed, and finalized your project moves into Programming and Production.

What Happens During This Step?

Programming – Our team of skilled CNC programmers prepares the necessary instructions based on your part’s design. They ensure that the machining or 3D printing process is optimized for precision and efficiency.

Production – After programming is complete, your part enters production. Whether it’s CNC machining or 3D printing, we utilize state-of-the-art equipment to bring your design to life with the highest level of accuracy and quality.

This step is where your vision is transformed into a physical part, produced to your exact specifications. We ensure all details are met and are constantly monitoring the process for quality control.

Step 7: Finishing and Quality Check

Once your part has been produced, it moves into the Finishing and Quality Check stage, where we ensure that every detail meets our high standards before it’s shipped to you.

What Happens During This Step?

Finishing – Depending on your specifications, we apply any finishing processes required, such as bead blasting, deburring, laser engraving, or any other surface treatments that are part of your order. If requested, we also provide anodizing, powder coating, or custom finishes to enhance the look and durability of your part.

Quality Check – Each part undergoes a thorough quality inspection to ensure it meets the tolerances, geometry, and finish requirements outlined in your order. Our team performs both visual inspections and precision measurements to ensure accuracy and consistency. If any discrepancies are found, we address them immediately to guarantee you receive the highest quality product.

After passing the quality check, your part is ready for shipping, and we prepare it for delivery based on the shipping method you've selected.