Instant CNC Machining Instant Quotes for Aluminum Parts

Streamlined Machining Backed by Standardized Tooling and Automation

At Rapid CNC Parts.com, we specialize in fast, precision CNC machining for custom aluminum parts. Our online instant quote system makes it easy for engineers, product designers, and makers to get reliable, U.S.-made components — from prototype to production. Upload your 3D CAD file today and get an instant quote in minutes.

CNC Machining Capabilities

3-Axis CNC Machining

The 3-axis CNC is the backbone of precision manufacturing in our shop, where the majority of parts with simple geometry are machined. With these machines, the cutting tool moves along the X, Y, and Z axes to shape material into precise forms—reliably and efficiently.

This process is ideal for:

- Flat or prismatic parts

- Pockets, slots, and holes

- Parts requiring tight tolerances with straightforward features

- Jigs, brackets, fixtures, covers, and enclosures

- Cost-effective production of prototype and low-to-mid volume runs

We support a wide range of machinable materials and can hold tolerances as tight as ±0.001", making our 3-axis milling a trusted go-to for rapid and repeatable results.

5-Axis CNC Machining

Our 5-axis CNC machines are built for complexity—enabling high-precision machining on multiple surfaces in a single setup. By rotating the part and cutting tool along five axes, we can achieve geometries that would be impossible or inefficient with traditional setups.

This capability is ideal for:

- Parts with compound curves, undercuts, and complex contours

- Reducing setup time and part handling for increased accuracy

- Aerospace, robotics, and medical components with multi-surface machining

- Jobs that demand tight tolerances and exceptional surface finish

- Minimizing fixture changes for faster, smarter production

If your design pushes the limits of manufacturability, our 5-axis machining helps you realize it with precision and speed.

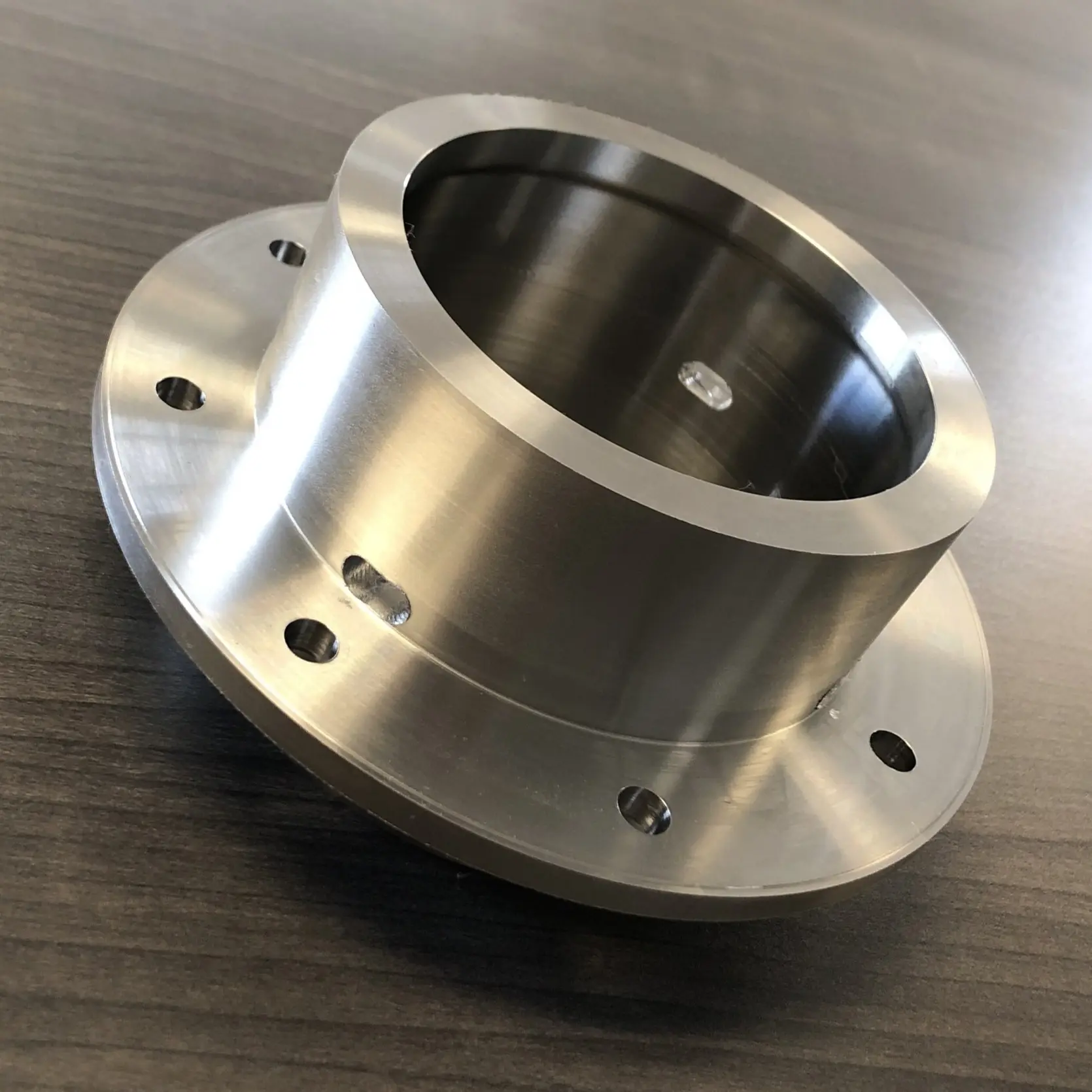

CNC Mill-Turn Lathe

Our CNC turning centers are tailored for round and cylindrical parts that demand accuracy, consistency, and clean finishes. Using high-speed lathes, we turn raw stock into precise components with external and internal features—ready for critical applications.

This service is ideal for:

- Shafts, bushings, spacers, pins, and other rotational parts

- Threads, grooves, and tapers with precision

- High-volume production where repeatability is essential

- Components that require smooth round surfaces

- Parts with strict concentricity and surface finish requirements

With tolerances down to ±0.0005", we’re ready to tackle your most demanding turning projects.

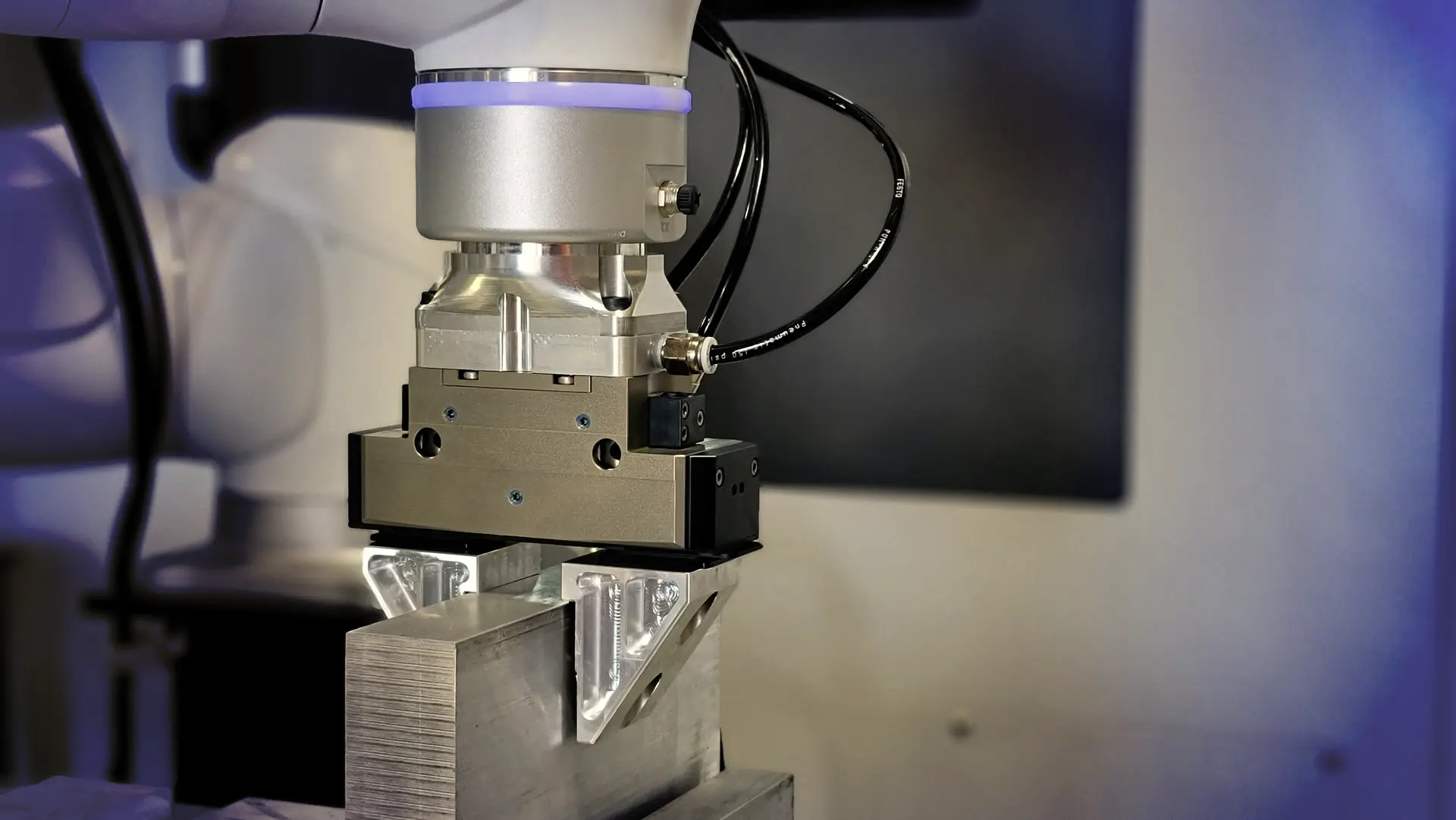

High Volume Production with Automation

To enhance speed and consistency, we’ve integrated collaborative robots (cobots) into our machining workflows. These safe, efficient robotic systems work alongside our operators to automate repetitive tasks like:

- Machine tending – Loading and unloading raw stock or finished parts

- Post-processing – Transferring parts between operations or to quality control

- Lights-out manufacturing – Running machines after hours to increase uptime

Our cobots help us keep lead times short, eliminate manual handling errors, and reduce labor costs—while freeing up our skilled team to focus on programming, inspection, and complex setups.

Our Machines: Built on DN Solutions Precision

At Rapid CNC Parts.com, our entire shop is powered by industry-leading equipment from DN Solutions (formerly Doosan Machine Tools). We’ve standardized our operations around these machines because they deliver the kind of accuracy, speed, and repeatability that serious rapid manufacturing demands.

By specializing exclusively with DN Solutions machines, we ensure consistency across every job—from prototype to production. These machines are engineered for performance and proven in shops around the world, and our operators are highly trained to leverage their full capabilities.

The result? Faster turnaround times, tighter tolerances, and fewer surprises—just precision parts you can count on.

Our Additional Services

Part Finishing Services

Machined parts often require more than just accuracy—they need the right surface finish, branding, or functional edge treatment. That’s where our finishing services come in. These value-add options complete the job with professional polish and attention to detail.

Deburring

Removal of sharp edges and leftover burrs for safe, clean handling

Laser Engraving

Permanent markings for part numbers, barcodes, logos, or serials

Bead Blasting

Uniform matte finish ideal for aesthetics or pre-coating prep

Tumbling

Gentle smoothing and polishing using vibratory media for mass finishing

Anodizing - Coming Soon!

We’re actively preparing to add anodizing services for aluminum parts—available in different options for corrosion resistance and a premium look.

Subscribe to our newsletter to stay tuned for the latest updates and service announcements as we add these and other addon services to our Instant Quote!

Need these services sooner? Add a note to your order to inquire with your order.

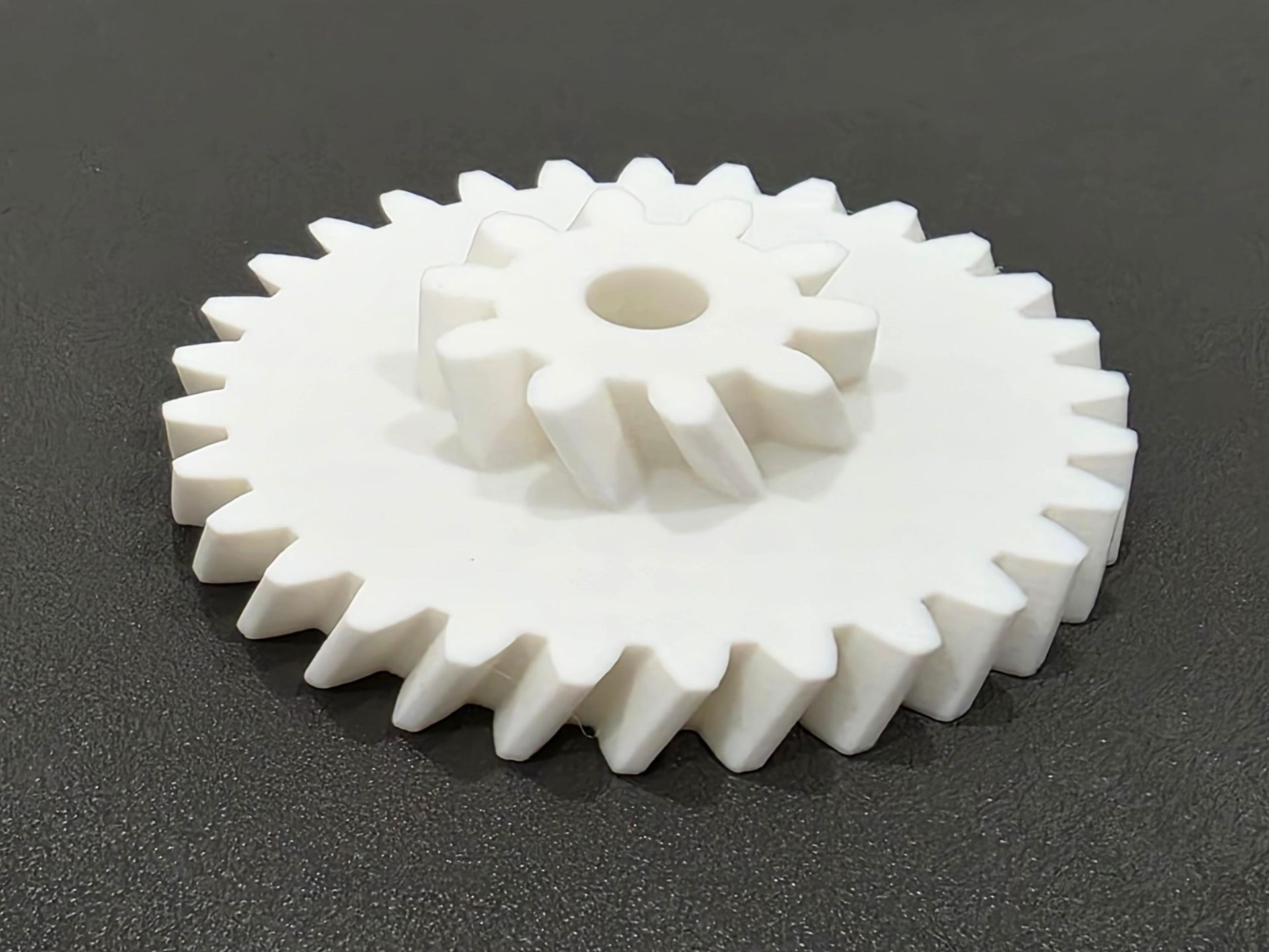

FDM and SLA 3D Printing (Rapid Prototyping)

Need a fast, affordable way to test your design before machining? Our 3D printing services provide flexible prototyping options using high-quality polymers for visual models, concept verification, and early-stage functional testing.

This service is ideal for:

- Proof-of-concept prototypes

- Checking fit and assembly before CNC machining

- Small runs of complex shapes or internal features

- Iterating designs without producing metal parts

- Reducing time-to-market during product development

We offer multiple material options and fast print turnaround, helping you bring ideas to life in hours, not weeks.

For example, instead of spending $300–$800 to machine a prototype aluminum part, many customers can 3D print a functional plastic model for $20–$50 in under 24 hours. That kind of flexibility lets you catch design flaws early—before you commit to expensive tooling or setups.

Reduction in design iteration cycles, enabling design improvements for final design

Often going from 2–3 weeks to just 1–2 days

Cost savings compared to prototyping with machined metal parts

Quality Inspection & Tolerance Verification

Every part that leaves our facility is inspected with care. Whether you need standard ±0.005" tolerances or demanding precision down to ±0.0005", we validate your critical features to meet spec before shipment.

Our quality process includes:

- Manual and digital inspection of key dimensions

- Checklists tied to your engineering drawings

- First-article inspection on request

- Traceable documentation and reports for regulated industries

- In-process checks for consistent results across batches

Quality isn’t an add-on—it’s a core part of our workflow.

The Future of Manufacturing Starts Here.

Get your project moving faster with our instant online quoting tool—experience precision and speed like never before.